For cleaning production equipment

PolySat® TX8723 pre-wetted cleanroom wipers are made from 100% melt-blown polypropylene with a cut edge, creating a soft wiper ideal for use on sensitive surfaces. TX8723 is pre-wetted with 0.2 µm filtered 70% IPA / 30% DIW for ease of use. The wipes provide a consistent, optimized cleaning efficiency with repeatable wetness and VOC levels. TX8723 PolySat® wipers are packaged in easy-to-use, peel-and-reseal bags, reducing solution evaporation that preserves the consistent wiper wetness level.

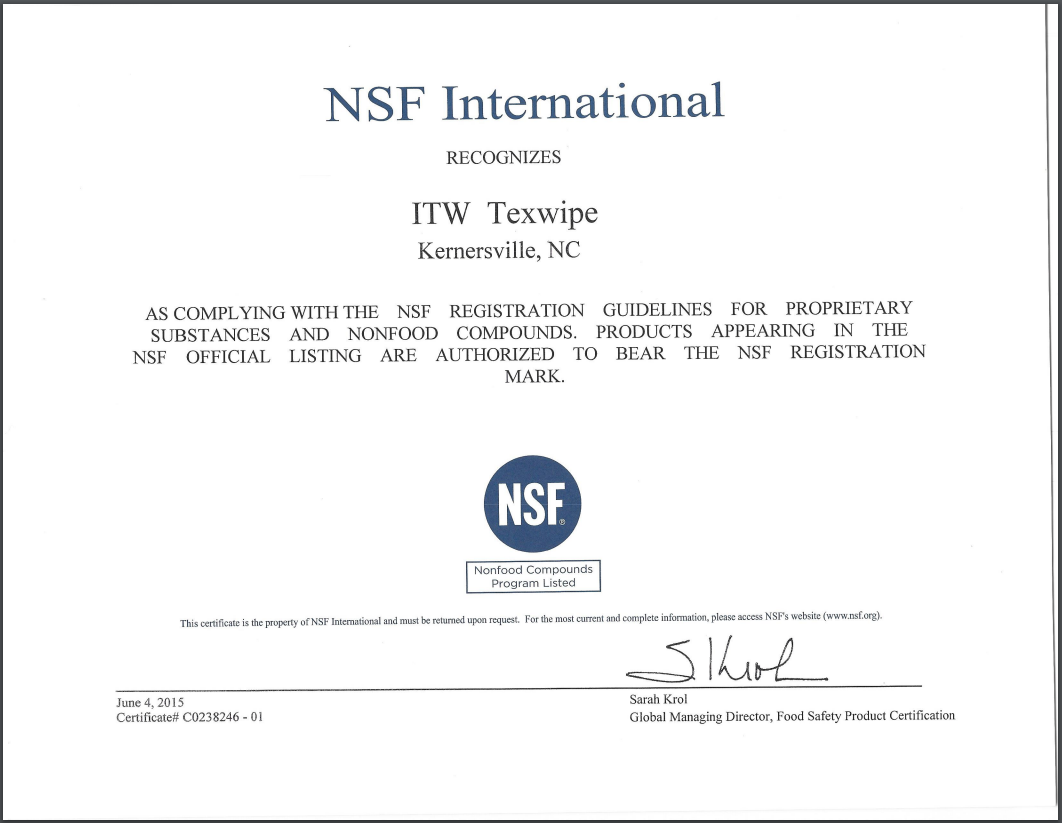

TX8723 PolySat® 70% IPA Pre-wetted Wipers are NSF-certified to be acceptable for use as a general cleaner (A1) on all surfaces in and around food processing areas, where its use is not intended for direct food contact. Use of TX8723 in food processing or handling facilities requires that all food products and packaging materials be removed or protected prior to use of product. A potable water rinse of cleaned surfaces is required after use of this product. When used according to instructions, TX8723 PolySat Wipers will not exhibit a noticeable odor nor will it leave a visible residue.

Material/Structure: 100% melt-blown polypropylene with a cut edge

Cleanroom Environment: ISO Class 5 - 8, Class 100 - 100,000, EU Grade B - D

Benefits:

- Manufactured to provide low levels of particles and extractables creating a wiper suitable for general cleaning and wiping

- Designed for use on abrasive surfaces. This wiper will not easily snag or abrade releasing particles and fibers into the process or environment

- Meets USP <797> and USP <800> wiper requirements.

Technical Data Sheet NSF Certificate, TX8723